Arc coating technology

Characteristic of the arc coating process:

- Arc evaporation takes place in the chamber.

- For arcing, conductive materials such as metals are mainly used as targets.

- A high degree of ionization is achieved in the chamber.

- Coatings deposited with arc coating technology exhibit excellent adhesion.

- A high separation rate is achieved in arc chambers.

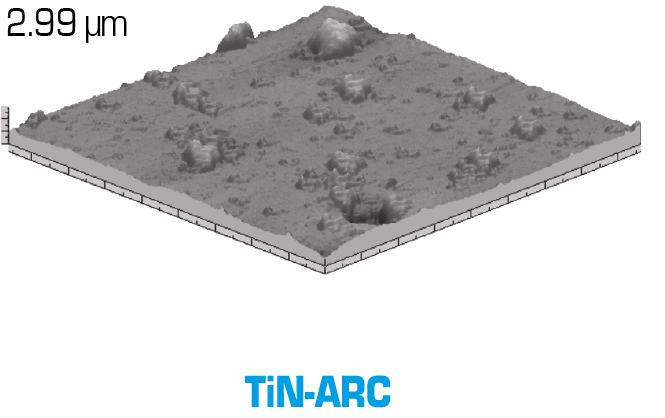

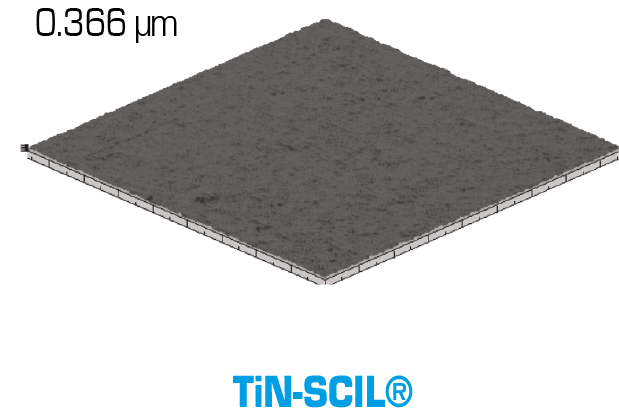

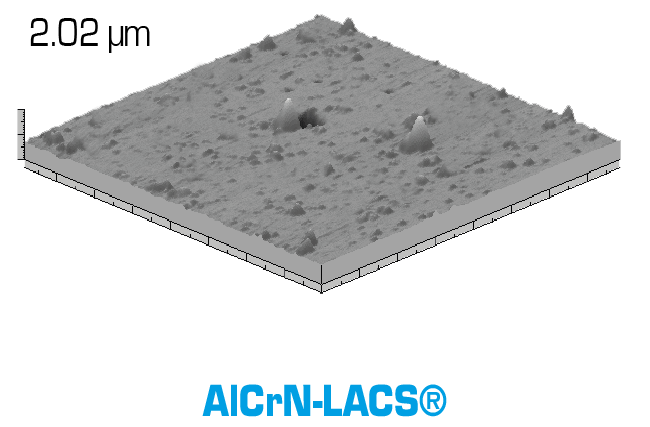

- The droplets produced by the arc process increase the surface roughness (Sa~0.2µm; Sz~2.1µm).

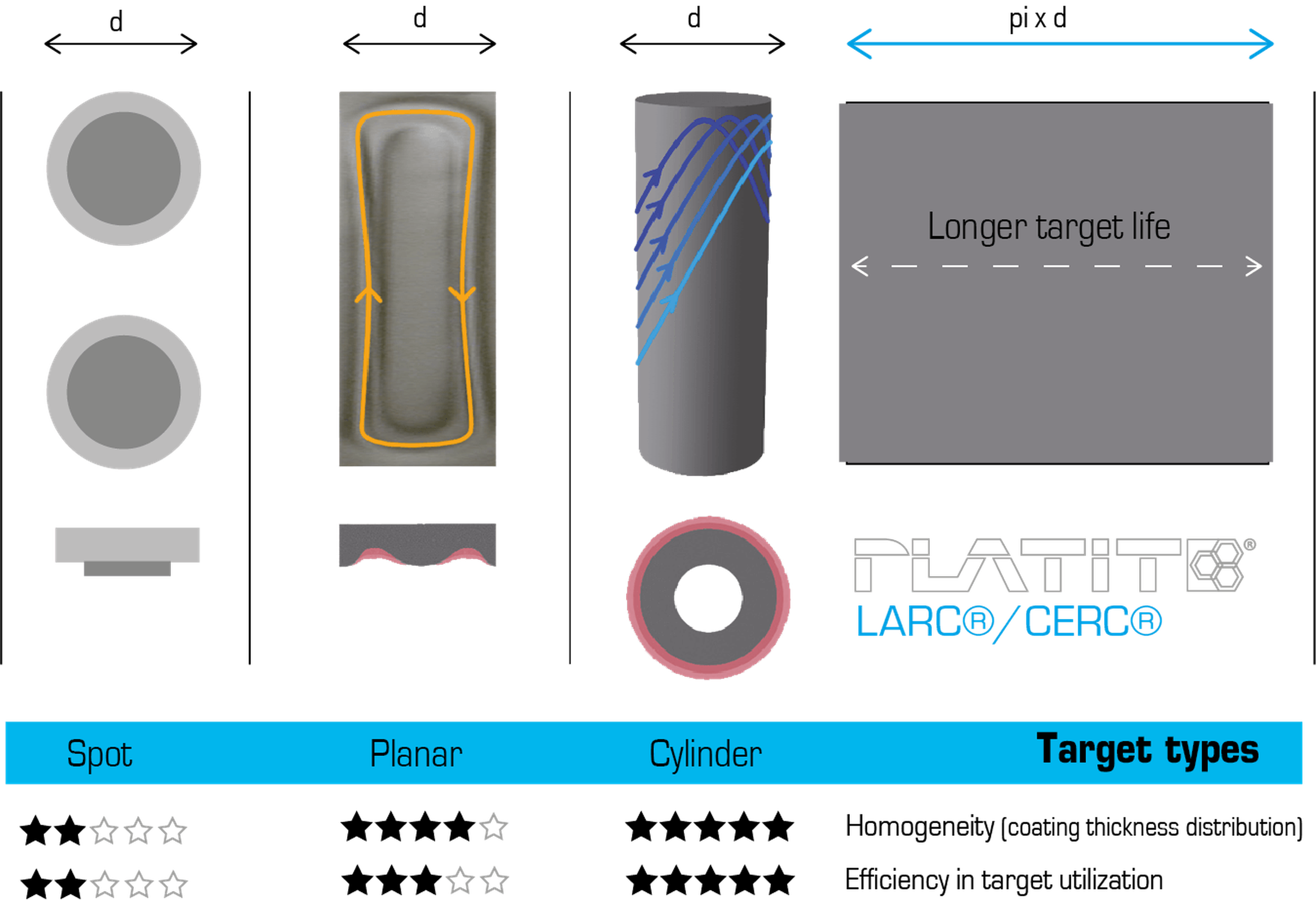

LARC® (LAteral Rotating Cathode) and CERC® (CEntral Rotating Cathode) are PLATIT’s proprietary brand names for rotating cylindrical cathodes with arc technology in the chamber door and in the middle of the coating chamber.

Compared to conventional cathodes, rotating cathodes have several advantages:

- The composition of a coating by unalloyed targets is flexibly programmable.

- A larger, more effective target surface area (pi x d) with a constant target length h (pi x d x h) extends the target service life.

- Rotating cathodes achieve excellent process control and stability.

- LGD® (Lateral Glow Discharge) etching can be used to achieve improved coating adhesion.

- A homogeneous vertical coating thickness distribution is created in the coating chamber.

- All rotating cathodes in PLATIT’s Pi coating units have a lifetime warranty with regular replacement at PLATIT cathode exchange centers.

Sputter coating technology

Characteristic of the sputter coating process:

- Targets with low thermal conductivity can also be sputtered, such as pure ceramics.

- A low degree of ionization prevails during the coating process.

- Improved adhesion can be achieved compared to conventional sputtering technologies, either through SCIL® (Sputtered Coating Induced by Lateral Glow Discharge) in the Pi411 PLUS SCIL® or through sputtering in the PL711.

- High deposition rates using SCIL®, for example 2µm/h with 2-fold rotation.

- Sputter coatings achieve a droplet- and defect-free smooth surface (Sa~0.02µm; Sz~0.3µm).

SCIL® sputter technology

To achieve high deposition rates during sputtering, our Pi411 PLUS SCIL® uses the patented SCIL® (Sputtered Coating Induced by Lateral Glow Discharge) process. SCIL® enables high-power sputtering from the central cathode.

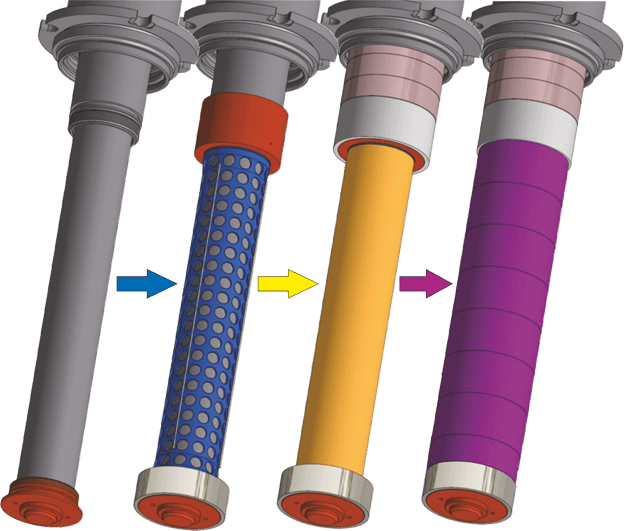

The cathode consists of these elements:

- Cathode body, including magnetic coils with up to 30 kW of sputtering power

- Perforated pipe for coolant inlet

- Membrane pipe tensed by internal cooling water for good conductivity to the target rings

- Target rings made of metal or ceramic

Hybrid LACS® technology – the best of both worlds

This unique combination achieves unimagined benefits:

- LACS® achieves a high ion density in the chamber.

- Excellent adhesion values are achieved.

- You have the possibility to dope arc coatings by sputtering, e.g., with ceramic or non-conductive materials, for completely new properties of the coating.

- The sputter portion results in much smoother coatings.

- Overall, the deposition rate is higher than with pure sputtering, but lower than with pure arc: up to 3µm/h with 2-fold rotation.

- The result is a superior surface quality compared to arc: Sa~0.1µm; Sz~1.6µm.

Here's how you can make hybrid technology work for you

The Pi411 PLUS LACS® coating unit allows you to use two different types of this hybrid technology.

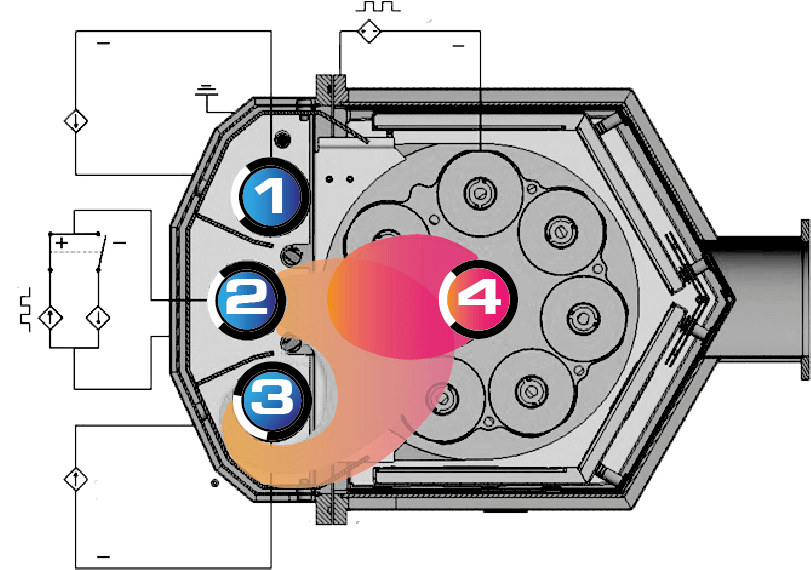

1. Simultaneous deposition by LGD® and SCIL®

To increase ion density and influence coating properties of sputtered coatings, you can use Lateral Glow Discharge and Sputtered Coating Induced by Lateral Glow Discharge simultaneously.

The setup is as follows:

- Cathode 1 - 3: LARC®

- Cathode 4: SCIL®

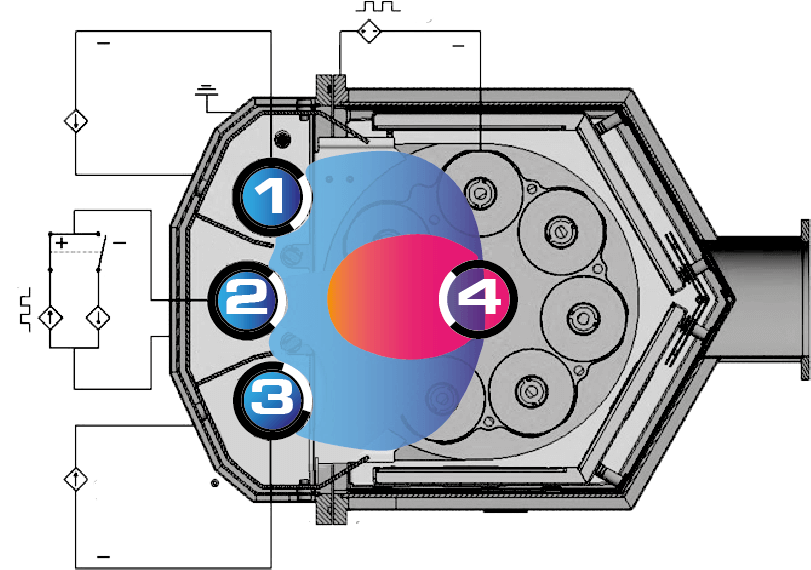

2. Simultaneous deposition by LARC® and SCIL®

For targeted doping of coating components, it is convenient to combine arc evaporation with LAteral Rotating Cathode and cathode sputtering with Sputtered Coating Induced by Lateral Glow Discharge.

The setup is as follows:

- Cathode 1 - 3: LARC®

- Cathode 4: SCIL®

More about

Learn more in the technical article (please click to open): “Hybrid Coating for Tooling”

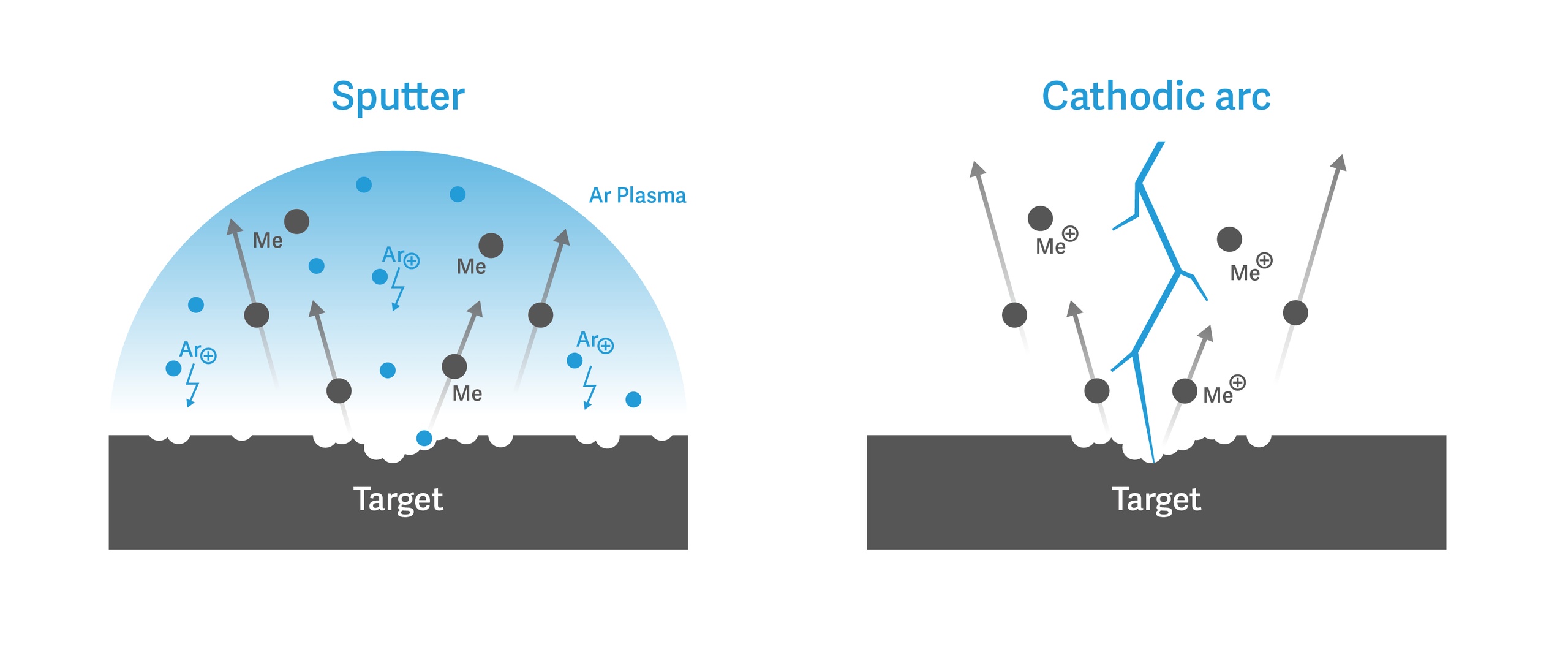

Arc and sputter – what are the differences?

Arc coating and sputter coating refer to two methods used to release ions from so-called “targets” in order for them to condensate (“deposit”) onto a material in a PVD unit, with which it forms a coating. The arc process uses an electric arc, i.e., a strong electrical discharge, comparable to lightning, which permanently strikes the target. In the sputtering process, on the other hand, the target is bombarded with high-energy ions (“cathode sputtering”), which causes the ions to detach from the target.

Both processes operate in a vacuum chamber under high vacuum, i.e., at a very low pressure. The hot gas (“plasma”) formed from the electrically charged molecules leads to a layer on the coated objects. Thus, the technical term for these coating processes is also “Physical Vapor Deposition” (PVD). The properties of the layers are influenced by the evaporated materials.

Arc processes are often used for tools that are made more resistant by hard coatings.

Sputtering processes are often used for functional components, decorative or medical parts and instruments.