Custom coating solutions for the PVD coating of rollers

Manufacturing processes in machining centers have driven capabilities to unimagined heights in recent years. They require tools that can withstand the highest loads in terms of rotational speeds, operating temperatures, cutting speeds and service life.

In addition, the finished coated surface must prevent the removed material of the workpiece from sticking to the tool. For this purpose, the coating unit must be as efficient as the tools that are PVD coated.

Rollers are a special case among tools: They are heavier than many other tools, and their size and special geometries alone make them a challenge for series coating units. Many conventional PVD coating units are simply unsuitable for coating them.

PLATIT solves the problems encountered in the coating of rollers

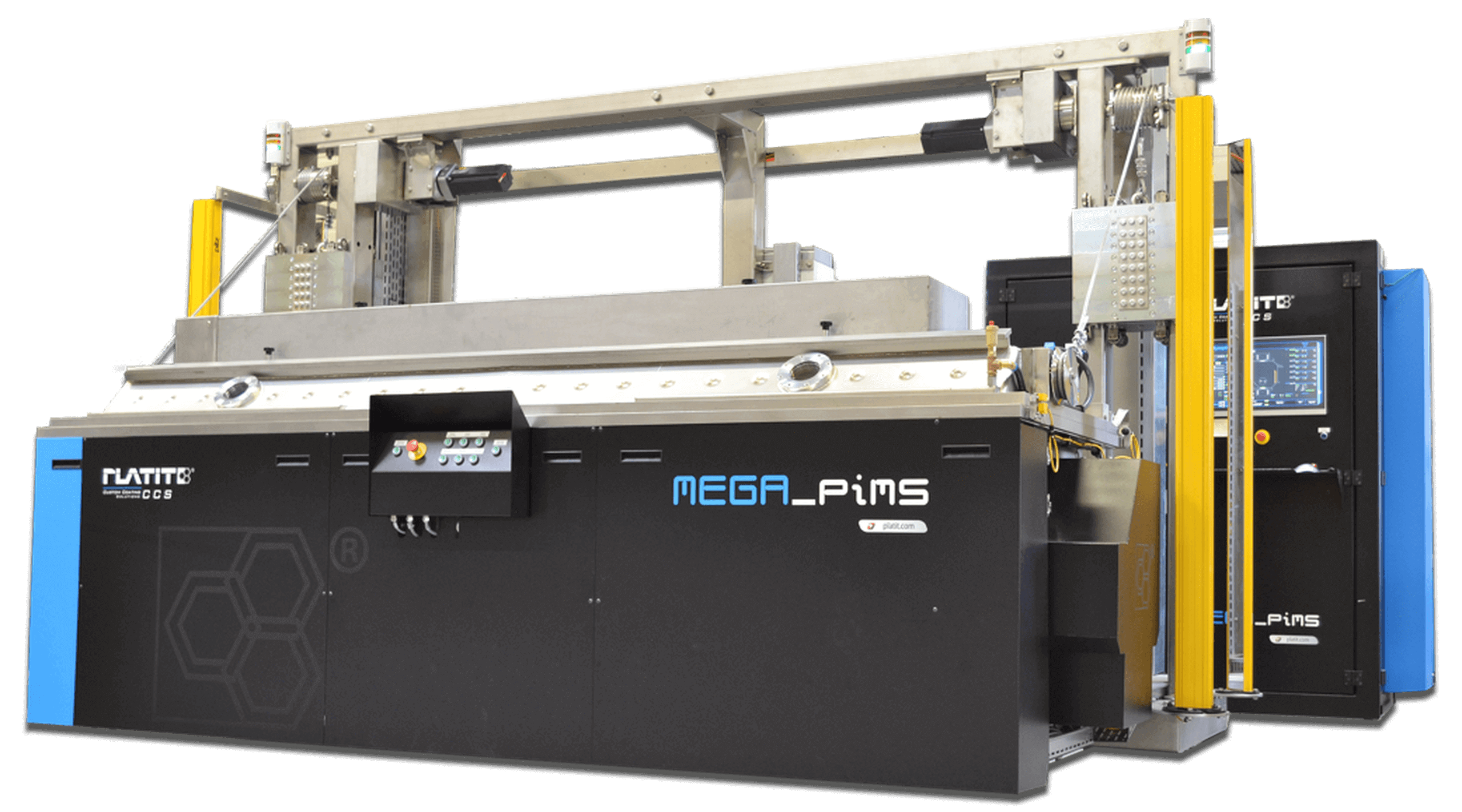

We have developed custom coating solution Mega-PiMS designed specifically for the PVD coating of oversized rollers, overcoming the problems of conventional units.

- Modern rollers are made of temperature-sensitive materials. Therefore, our unit operates with processes in a low temperature range.

- Pulsed DC magnetron sputter coating technology ensures an extremely smooth, defect-free surface.

- A large chamber volume is required to work as efficiently as possible. The large vacuum chamber of the Mega-PiMS offers the best conditions for this.

- As with a standard coating system, the holders are adapted to the tool to be coated: Dummies are added when a full batch needs to be simulated. The aim is to achieve a homogeneous coating thickness distribution and a uniform microhardness of the coating.