The video, starting at minute 17:33, explains the seven steps to high-performance coating in more detail.

Special PVD coatings are applied to optimize the properties of the tool steel for the specific application. These are primarily hard coatings based on titanium nitride (TiN), titanium carbonitride (TiCN) or titanium aluminum nitride (TiAlN), as well as chromium nitride (CrN) and aluminum chromium nitride (AlCrN). These materials are increasingly used today to set the required properties. It not only allows higher microhardness to be produced, but also longer tool service lives to be achieved and challenges due to removed chips to be avoided.

PLATIT also continuously adapts the coating systems required for the coating of tools to the current requirements and is always developing them further. The PVD coating units that can produce such high-performance coatings are among the best in the world and are used by tool manufacturers around the world.

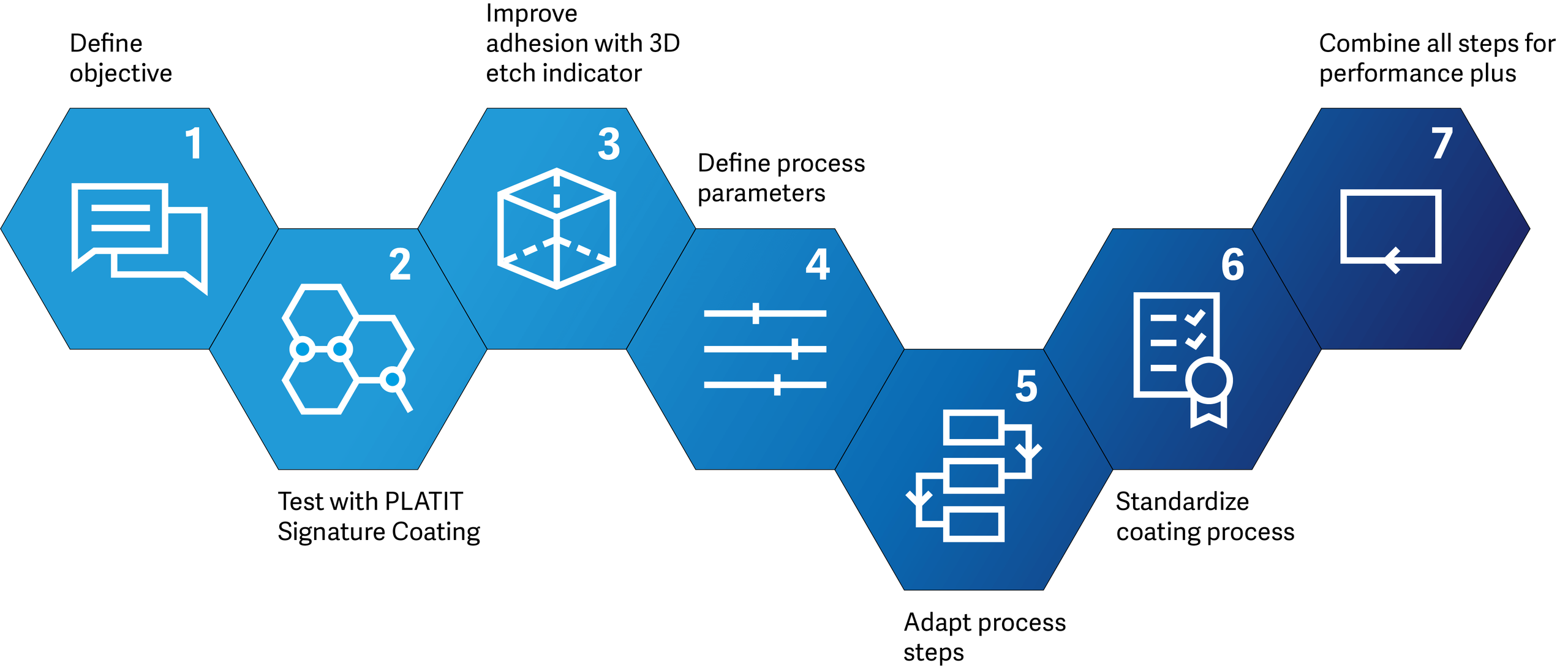

Seven steps to high-performance coating

We follow this basic concept in 7 steps to prove to our customers that they can improve their status quo.

It all starts with an initial discussion, benchmarking, and determining what the challenge is in the coating application.

Based on this, we coat tools with a coating from our existing portfolio. Only after evaluating the first joint results, we jointly decide whether a coating should be further developed or optimized with regard to the challenges of the respective application.

This includes first optimizing etching as part of PVD coating development. This is where our etch indicator comes into play. It’s a step in which the tool surface is prepared in such a way that it can adhere extremely well to the substrate. If you compare a standard coated version with one that uses an optimized etching process for your application, the added value of dedicated etching can be clearly seen.

Due to our unique cathode technology, it is possible to define the proportion of different alloy components in the coating together very flexibly. For maximum productivity in subsequent production, the alloy components are mixed as standard in a cathode in such a way that a maximum shortened coating process time has a positive effect on the service life of your tools.

Finally, in addition to the coating development, we also adapt the pre- and post-treatment of your tool exactly to your application.

Thanks to this process, we ensure your performance plus in the PVD coating industry and you achieve the desired coating properties on your tools.

- Discussion of the initial situation and definition of the objective

- Performing test runs with PLATIT Signature Coatings to generate the ideal coating composition

- Improvement of coating adhesion through optimized plasma treatment using 3D etch indicator

- Optimization of all coating parameters by using the “Dedicated Coating Development” process, e.g., coating structure, coating thickness and functional adhesion layer to reduce friction

- Adaptation of upstream and downstream process steps such as edge pre-treatment and edge post-treatment or polishing

- Preparation for series production by selecting suitable target alloys

- Go through and combine all steps together until the desired “Dedicated Coating” is generated