The video, starting at minute 08:07, explains how investing in your own coating center pays off after just a short time.

Complete coating units as turnkey solutions

Our turnkey solutions are designed to ease your biggest worries: That something is overlooked in the planning of your coating center that later leads to additional costs, inefficiency, or errors in the overall process. We incorporate our decades of experience into complete solutions for you, creating a successful, functioning coating center that precisely meets your specifications.

Perfect PVD coatings are created in a complex process that begins long before the vacuum chamber. From decoating and cleaning to quality control, each step must be coordinated and fit together. We provide and integrate all necessary components and process steps for a successfully operating coating center for hard coating.

As your partner, we take responsibility for the functionality and reliability of the overall system, exactly according to your needs. The turnkey solution for your coating center covers all areas.

- Depending on the requirements, different dimensions of coating chambers for the PVD coating of small to oversized substrates

- Equipment for decoating high-speed steel and carbide

- Equipment for precise edge pre-treatment

- Ultrasound cleaning systems

- Measuring devices for easy quality control of coating results

- Equipment for post-treatment, such as a polishing

- PVD production accessories from sleeves to handling systems and chillers

- Imparting of the full coating know-how to the specialists in trainings and manuals

We work with partner companies to offer you a wide range of peripherals for upstream and downstream steps of a coating process.

Flexibly tailored to your respective application, our processes are integrated into your tool production. Thus, we ensure independent, stable, and innovative production in your PVD coating center.

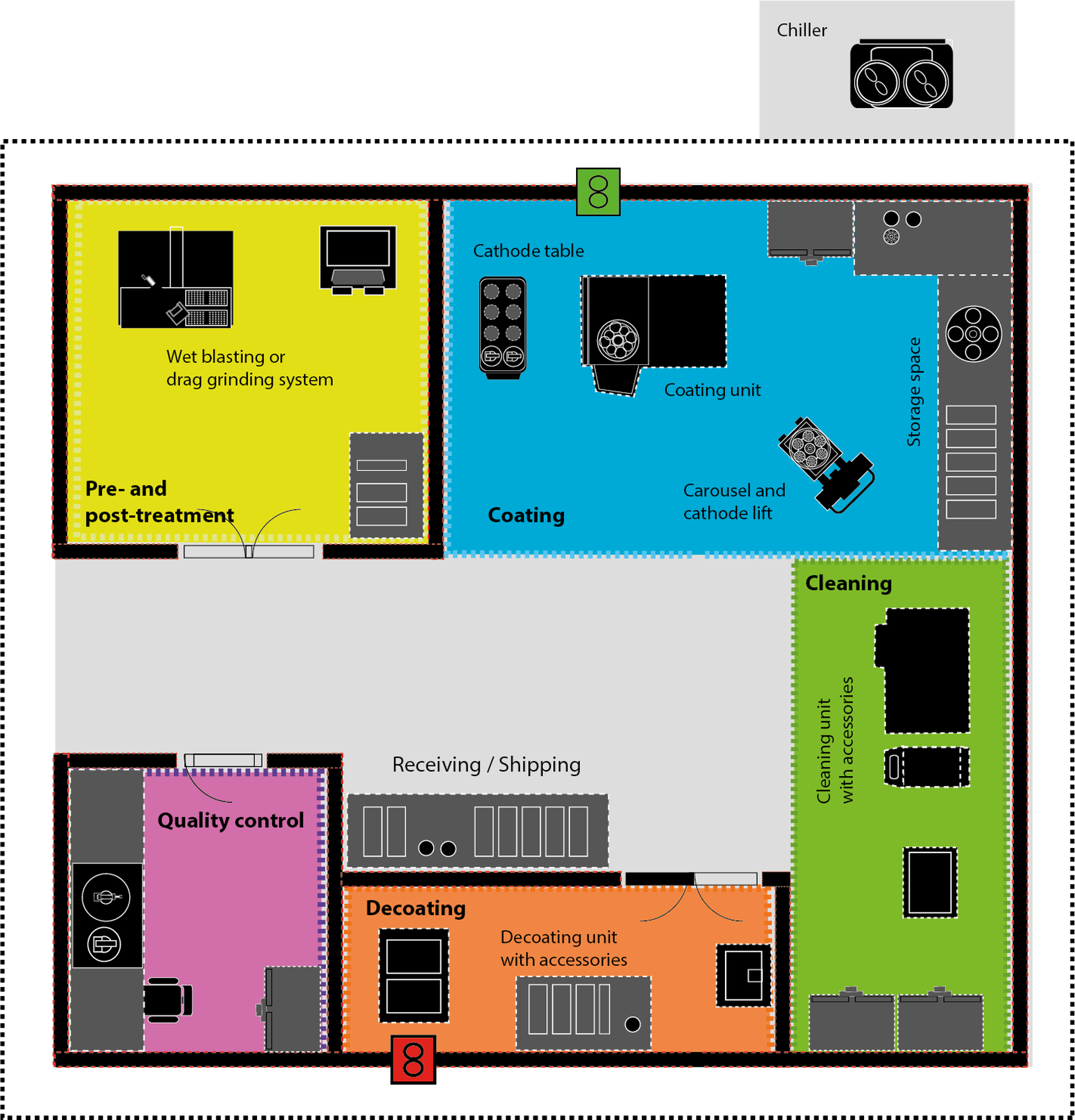

Typical workflow in a coating center designed by us

The result of our complete solutions considers all necessary process steps around an efficient and highly integrated coating unit. It also incorporates best practices from our decades of experience.

This includes, for example, that some modules (decoating, edge pre-treatment and post-treatment) are ideally set up in a separate room so that the PVD coating process is not adversely affected. The chiller can also be placed in a separate room.

In our turnkey solutions, all interlocking steps are spatially arranged in such a way that effective processes are created, and the available space is optimally utilized:

- Incoming goods

- Cleaning

- Optional: Decoating

- Optional: Edge pre-treatment

- Fine cleaning

- Preparing for coating

- Coating

- Unloading a batch

- Optional: Post-treatment

- Quality control

- Outgoing goods

When is an in-house coating center worthwhile?

Find out more here: In-house coating