Edge pre-treatment and edge post-treatment

Pre-treatment and post-treatment of the edges are very important processes in the turnkey system in order to exploit the full potential of a PVD coating.

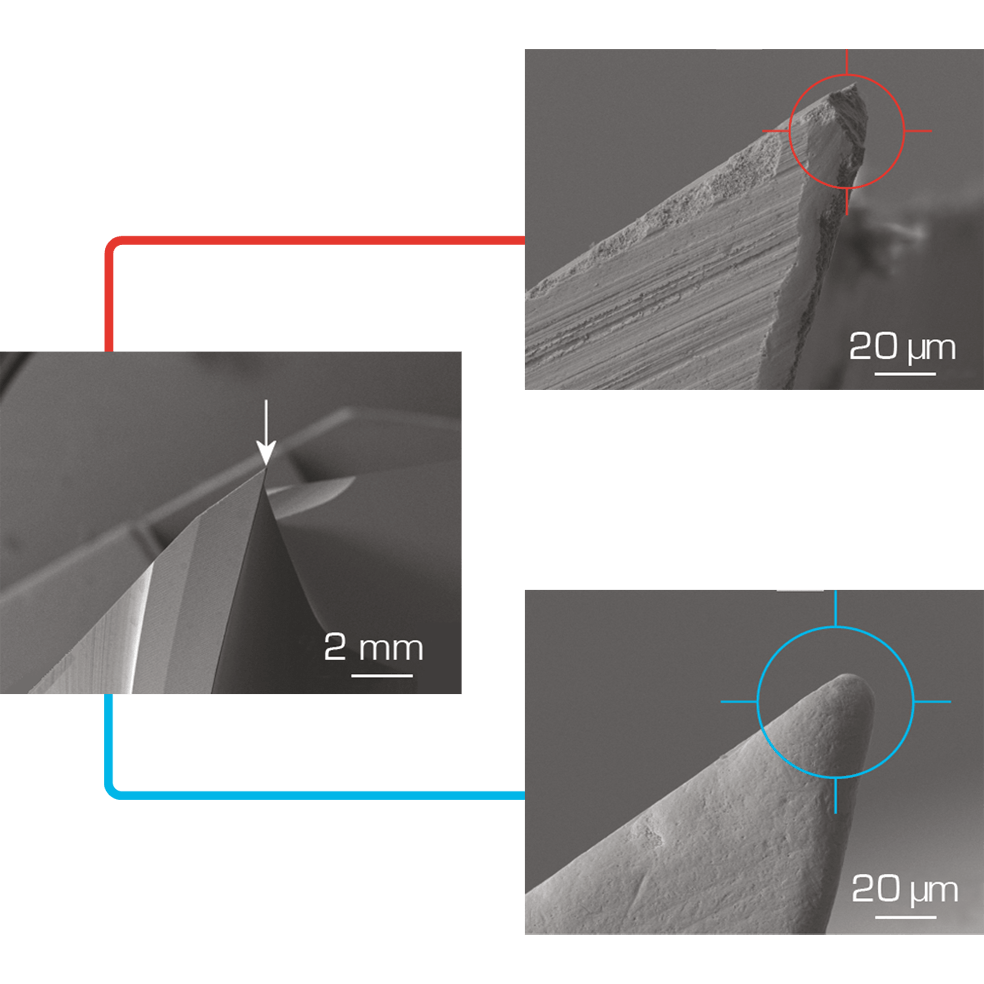

The main objective of edge pre-treatment is to increase the stability of a cutting-edge and thus the performance of a tool.

Advantages of cutting-edge rounding

- Reduces chipping along the edge

- Reduces the so-called “antenna effect” in PVD coatings on sharp edges and thus reduces the stress in a coating

- The more an edge is rounded, the thicker coating is possible

- Higher cutting-edge stability

- Avoids chipping of the cutting-edge as well as chipping of the coating during the machining process

- Increase in tool life despite “blunt” cutting-edge

Edge post-treatment

One of the problems that can arise without post-treatment of the surfaces is the jamming of chips. This can result in the tool, e.g., a drill, breaking.

Objectives of the edge post-treatment

- Removal of droplets after PVD coating

- Reduction of surface roughness

- Improved chip-flow for cutting tools

If the post-treatment is too strong, the cutting-edge can be exposed. This leads to:

- Immediate, full, and direct contact of the cutting-edge with the workpiece material

- Low heat and chemical insulation

- Low coating thickness near the cutting-edge

- A larger cutting radius, which creates a larger area without a coating

- The impression of a defective PVD coating

The most common edge pre-treatment methods are:

- Dry blasting

- Wet blasting

- Drag finishing

- Brushing

- Magnet finish

The most common post-treatment methods are:

- Wet blasting

- Drag finishing

- Polishing blasting

PLATIT has a broad expertise in edge pre- and post-treatment for PVD coating. We offer and integrate all the products necessary for the turnkey system.

For more information on pre-treatment and post-treatment procedures, see our compendium on pages 101 to 105 and on page 109 by clicking here or contact us directly.